Harland & Wolff on the Thames

London was still the largest and busiest port in the United Kingdom, however, with a huge number of ships coming and going every week, and the river and its docks were full of tugs, barges and lighters. It therefore made sense for Harland & Wolff to open a repair and engine works, which opened beside the entrance lock of the King George V Dock at Manor Way in North Woolwich in 1924.

The North Woolwich site was the largest of six Harland & Wolff yards around the London docks, the others being at the West India Docks and the Millwall Dock that were both on the Isle of Dogs, the London Docks at Wapping, the Surrey Commercial Docks at Rotherhithe, and the Tilbury Docks downriver in Essex. The North Woolwich yard covered nine acres, with the foundry taking up about half the total area.

During its time, the North Woolwich site was the largest of any shipyards on the Thames. It specialised in building smaller steam ships, barges and lighters, and buoys and piers. Other general engineering work was also carried out at the works, including producing metalwork for Ford motors at Dagenham, maintenance work on PLA locomotives, and metalwork for railways. Almost everything needed to fit a vessel could be produced on-site, whether it was a propeller-shaft or a brass screw, as well as the tools that were used to make them. The works were capable of manufacturing lengthy shafts and boilers, and sails, and the forge could produce castings up to 15 tons. A railway line came into the yard along the riverside from the PLA’s rail network that ran around the King George V Dock.

The North Woolwich works employed a wide variety of skilled workers, including shipwrights, fitters, blacksmiths, moulders, boilermakers, platers, tinsmiths, coppersmiths, pattern-makers, carpenters, upholsterers, painters, electricians, riggers and caulkers, and crane drivers. Another group of skilled workers were the sail-makers because there were many Thames sailing barges operating on the river and around the coast until the Second World War. The foremen at the works stood out from the other workers because they were the ones who wore bowler hats.

John Fox underwent an apprenticeship at the yard in the 1940s. He later recalled:

Amid all these [parts of the works] I would roam, why even today the scent of the sail making loft still lingers. There were a lot of tarpaulin covers used then and the inviting tang of a thousand jumbled odours as you climbed up the stairs into their sail making shop is still with me, like walking into another age. Yet another relic of bygone life was the general office. There banks of clerks sat on tall stools working on chest-high wooden sloping desks, dipping their pens into ink inkwells.

John was one of many young men who joined the firm and took up an apprenticeship, learning particular skills under the tutelage of experienced workers. In his first year he earnt 18 shillings a week, or 90 pence in modern money. When young men completed their apprenticeship they were expected to leave the firm and join another company, possibly to return later with greater experience.

Harland & Wolff had a second site at the western end of the King George V Dock, around a mile from the main site, where the London City airport terminal is now located. This was from where work on ships in the graving dock, or generally moored in the docks, was managed. ‘Graving’ is old nautical term from days of sailing ships, meaning cleaning, painting, tarring ship’s hull when ships small enough to be beached. It continued in use in the 20th century to mean dry dock. Boilermakers, electricians and plumbers all worked in ships’ engine-rooms. Gangs of men had to lift huge engine parts in and out of ships, while scalers did the dirty work of climbing into ships’ boilers for de-scaling. Laggers maintained asbestos lagging on pipes, not then knowing of the dangers of asbestos. Much of the work was on ships of the Union Castle line, which operated between London and South Africa, that had been built by Harland & Wolff in Belfast.

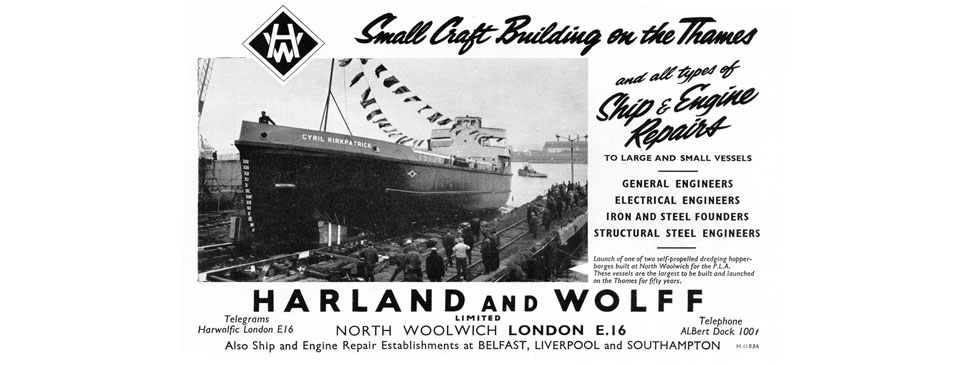

Small vessels such as lighters were often constructed on the company’s slipway at North Woolwich. The small cement carrying ship the Claycarrier was constructed there in 1932. It was a much smaller vessel than those built at the Belfast and Clyde yards but was nevertheless the largest launched on the Thames in the previous 25 years.

In the 1930s Harland & Wolff also had a contract at North Woolwich with the Grand Union Canal Carrying Company, a subsidiary of the company that owned the Grand Union and Regent’s canals, to build narrowboats to work on the canals. Grand Union canal narrowboats worked in pairs, with a motorised engine boat pulling the engine-less ‘butty’ boat. Forty-four pairs of narrowboats were built between 1935 and 1936, each boat named by the canal company after stars, planets and constellations, such as Saturn, Venus, Mercury and so on. They were of composite construction, with steel hull sides and flat wooden bottoms. The motor boats were fitted with diesel engines manufactured by the Russell Newbery company.

In 1936 the canal company decided it wanted additional boats that had a deeper draft to be able to carry more cargo, so a further 36 pairs were ordered, fitted with National company engines, the last of which was built in 1937. These deeper boats were named after towns and villages and were henceforth known as ‘Big Woolwich’ boats, with the earlier, shallower boats known as ‘Small Woolwich’. The names of the Big Woolwich boats begin with Aber, which is a village in Wales, and ended with Hawkesbury, a village in Gloucestershire. Names later in the alphabet were built by other boatyards.

London’s docks were a major target throughout the Second World War. On 10th February 1945 a German V2 rocket landed on the King George V dock gate, just yards from the Harland & Wolff building. Three people were killed and many of the clerks in the general office and draughtsmen on the top floor were badly injured.

In the early 1960s the North Woolwich yard was building small craft such as a floating marine fuel refilling station, built for Esso. One notable vessel constructed on the slipway was the small ship the Cyril Fitzpatrick, named after the former chief engineer of the PLA and launched in 1964. Perhaps the last vessel built at North Woolwich was the 1000-ton bulk cement carrier Blue Circle, launched in 1971.

By the early 1970s shipping was moving away from London to other ports. With orders drying up the North Woolwich yard closed in 1972. The works were demolished and in the following years the site was cleared to make way for the Galleons Point housing estate.

All that remains of Harland & Wolff North Woolwich are the works’ gates. They were saved, as were two other sets of gates from other Harland & Wolff sites. In 1994 the North Woolwich gates were erected in Lyle Park at Silvertown, a short distance from the old works. Lyle Park had opened in the same year as Harland & Wolff North Woolwich and had been a gift to the local people from the Abram Lyle Golden Syrup factory.

Sources include: Graces Guide to British Industrial History; Greenwich Industrial History Society, Harland & Wolff Shipbuilding & Engineering Works (www.theyard.info).

< Back to The Port of London